Our Core Services

Operational Efficiency Assessment: From Fundamentals to Advanced Strategies

Having a hard time with inefficient processes that drain your resources? An operational efficiency analysis helps you pinpoint where your business is wasting time, money, and effort. Whether you own a startup or operate an established company, having a clear idea of how to analyze and optimize your operations can be the difference between succeeding and just surviving in the competitive economy today.

Table of Content

What is Operational Efficiency Assessment?

Operational efficiency evaluation of operations is a formal evaluation process that looks at how well your company translates inputs (time, resources, labour) into outputs (service, product, revenue). It is different from a business review in that it targets specifically the efficiency of how well your operations function, and what wasteful processes can be removed or optimized.

This evaluation goes in-depth into your workflows, resource utilization, and performance measurements to identify areas for improvement that have a direct impact on your bottom line. By examining every function of your business operations—supply chain to quality control—it identifies workable ways to accomplish more with less without reducing quality or improving it.

Why It Matters for Your Brand or Business

Performing routine operational effectiveness evaluations provides real return on investment that directly impacts your business success:

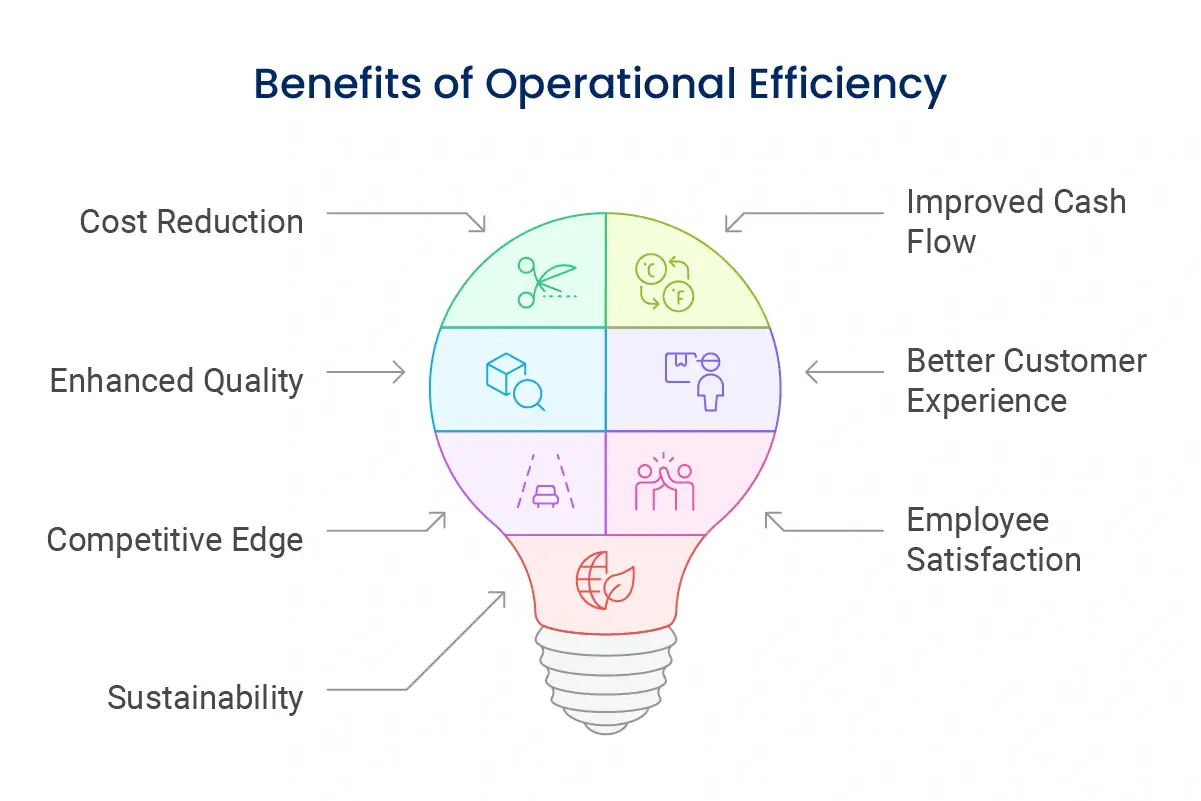

Cost Reduction

Weeding out wasteful processes can reduce operational expenditures by 15-30% without diminishing quality

Improved Cash Flow

Efficient operations translate to faster production cycles and more rapid time-to-market

Enhanced Quality

Efficient processes most often result in fewer errors and defects

Better Customer Experience

Efficiency gains often result in faster delivery and quicker responsiveness

Competitive Edge

Being operationally efficient enables you to provide better value for money or greater quality than your competitors

Employee Satisfaction

Eliminating infuriating bottlenecks and wasteful work improves staff morale

For small businesses and new business startups particularly, operational efficiency can make or break the business in tough economic times when every penny saved counts.

Types of Operational Efficiency Assessments

Different assessment approaches suit different business needs. Here are the key methodologies to consider:

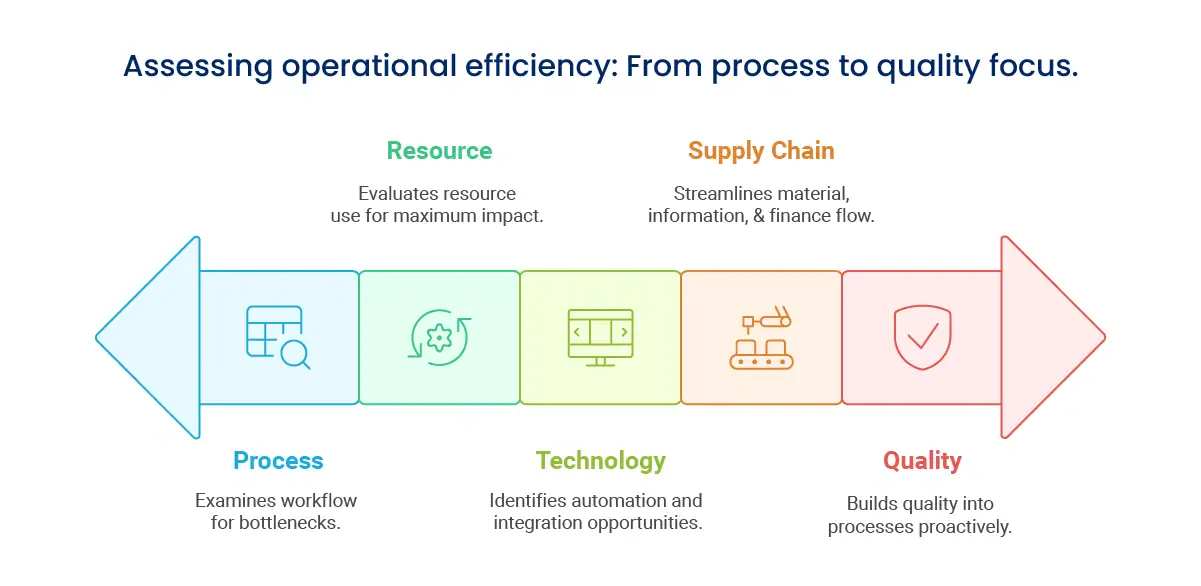

Process-Focused Assessment

This assessment type examines workflow sequences, identifying bottlenecks, redundancies, and inefficiencies in how work moves through your organisation. It’s particularly effective for businesses with complex, multi-step operations.

Process-based evaluations assist companies in eliminating wasteful steps, decreasing handoffs between departments, and designing smoother workflows that save time and minimize errors. Small manufacturing companies frequently experience spectacular improvements following improvements in process inefficiencies.

Resource Allocation Evaluation

This evaluation checks to see how well you’re leveraging your resources—people, machines, buildings, and capital. It assists in pinpointing underutilized assets and chances to reallocate resources for optimal return on investment.

Effective resource allocation planning avoids resource deficiencies which cause bottlenecks and overcapacity that costs money. For instance, retail operations can greatly enhance profitability through the optimisation of staff scheduling according to peak customer traffic periods.

Technology Utilisation Assessment

This evaluation takes a look at how effectively your technology infrastructure enables your business. It determines areas for automation, integration of standalone systems, and implementing more effective tools.

Most businesses have a hodgepodge of systems that don’t talk with one another well, and this causes time-wasting workarounds and errors. Small companies can usually gain phenomenal efficiency with specifically targeted technology enhancements that eliminate burdensome handwork.

Supply Chain Efficiency Assessment

This evaluation examines the movement of materials, data, and funds from suppliers through customers. It finds areas to streamline the supply chain, vendors to consolidate, and inventory to optimize.

A lean supply chain minimizes carrying costs, reduces stockouts, and enhances cash flow. Retail and online shopping companies especially gain from streamlining their supply chain activities to lower lead times and inventory holding expense.

Assessment of Quality Control Systems

This assessment measures the impact your processes for managing quality have on efficiency. It shows potential areas for creating quality into processes instead of inspecting it afterward.

Efficient quality control avoids expensive rework, returns, and warranty claims. Both manufacturing and service firms can increase efficiency by fixing quality problems at their source instead of suffering the aftermath.

Elevate Your Brand’s Look—Start Your Custom Color Palette Today!”

How to Conduct an Operational Efficiency Assessment: Step-by-Step Guide

Do these to perform a comprehensive analysis of your business operations:

Define Clear Objectives

Begin by determining precisely what you wish to accomplish. Do you want to cut costs by a percentage point? Increase production time? Increase customer satisfaction scores? Having clear, quantifiable goals allows you to target areas for your assessment that will create the greatest impact.

Map Current Processes

Take detailed notes of your current processes. Value stream analysis and process mapping can be used to visualize how work actually moves through your organization. Take pains to record every step, handoff, decision point, and waiting time. swim lane diagrams are useful tools to use here.

Collect Performance Data

Record pertinent metrics on your operations as they are now. This could comprise cycle times, error rates, usage of resources, cost, and quantity of output. Performance metrics tracking is the quantitative basis for determining areas for improvement.

Identify Bottlenecks and Waste

Examine your process maps and performance metrics to identify: Bottlenecks that hold up the whole process Redundant steps that fail to add value Long waiting periods between activities Rework loops due to quality problems Inefficient movement of materials or information

Implement and monitor changes

Implement your plan systematically, beginning with pilot projects where feasible. Monitor key performance indicators during implementation to verify changes are realizing the anticipated benefits. Be ready to modify your approach based on actual results.

Develop Improvement Strategies

From your findings, develop detailed plans to tackle each inefficiency you've identified. Prioritise improvements on: Likely impact on key metrics Resource demands for implementation Time to realise benefits Alignment with wider business objectives

Create an Implementation Plan

Construct a comprehensive plan for implementing your improvement initiatives. Have: Specific steps and outcomes Resource needs Schedule with milestones Responsible for each activity Change management implications

Benchmark Against Best Practices

Benchmark your performance against industry norms or best-in-class operations. This sets realistic improvement targets and can even highlight approaches you haven't thought of.

Recommended Assessment Tools and Methods

The proper tools can make a huge difference in the quality and productivity of your evaluation:

Diagnostic Tools

Process Mining Software

Software such as Celonis or UiPath Process Mining automatically processes process data from your IT systems to generate correct process maps and reveal inefficiencies.

Value Stream Mapping

Lean management method that captures, analyzes, and optimizes the flow of information or materials needed to manufacture a product or service.

Fishbone Diagrams

Assist in isolating root causes of inefficiency by studying the possible reasons in areas such as people, processes, equipment, materials, environment, and management.

Statistical Process Control

Applies statistical techniques to measure process performance and detect variations that signify inefficiency.

Analytical Methods

Time and Motion Studies

Close scrutiny of the time required for certain operations and physical movements in relation to such operations, to determine wasted motion and unproductive sequences.

Capacity Utilisation Analysis

Looks at the extent to which your resources (equipment, staff, facilities) are being utilized in comparison to their maximum capability.

Cost-Benefit Analysis

Assesses possible enhancements by weighing the implementation cost against perceived advantages.

Simulation Modelling

Produces computer models of your operations to experiment with improvement scenarios prior to applying them in the actual world.

Common Mistakes and Pitfalls in Operational Efficiency Assessment

Steer clear of these common mistakes that can render your evaluation ineffective:

Focusing Only on Cost Cutting

Efficiency is often sought by companies with a sole emphasis on expense reduction, disregarding potential value-creation opportunities. Real operating efficiency intersects cost savings with quality improvement and value creation.

Solution: Define efficiency as value created per unit of resource used, rather than solely cost reduction. Include customer experience effects in addition to financial measures.

Neglecting Employee Input

Front-line workers typically possess the best understanding of operational problems and possible solutions. Not engaging them in the evaluation process is a loss of valuable insights.

Solution: Design formal methods for soliciting input from employees at all levels, e.g., workshops, surveys, or improvement teams. Their on-the-job knowledge is precious for determining realistic improvements.

Implementing Too Many Changes Simultaneously

Striving to correct everything simultaneously usually results in change fatigue, insufficient focus, and poor implementation. This strategy can actually reduce productivity in the short run as individuals have difficulty adjusting to multiple changes.

Solution: Prioritize improvements by consideration of influence and feasibility. Make changes in reasonable phases which support appropriate adjustment and monitoring of outcomes before proceeding to the subsequent set of changes.

Measuring the Wrong Things

Utilizing inadequate or wrong metrics may result in distorted inferences. For instance, concentrating on labour productivity alone may lead to practices cutting down on quality or customer satisfaction.

Solution: Build a balanced set of performance indicators that cover efficiency, quality, time, and customer experience factors. Align metrics with your strategic goals.

Advanced Operational Efficiency Strategies

After having solved the basics, look at these more advanced methods to optimize your operational efficiency further:

Measuring the Wrong Things

Go beyond crisis management by employing predictive analytics to forecast operational problems ahead of time. By examining trends in your performance data, you can predict impending bottlenecks, maintenance requirements, or resource deficiencies in advance of causing interruptions.

For instance, a restaurant could apply historical information and forecasting algorithms to predict peak times more accurately, which can be used for more accurate scheduling of staff and stock management.

Cross-Functional Process Integration

Do not look within departmental silos, but instead look outside them in order to optimize end-to-end processes. Frequently, the greatest inefficiencies are in handoff points between departments. By stepping back and rethinking processes across functional boundaries, you can eradicate these handoff inefficiencies.

A retail company could combine its purchasing, stock management, and sales forecasting functions to achieve a smooth movement of information that minimises both stockouts and inventory surplus.

Strategic Outsourcing and Partnerships

Find out what can be done better by other people compared to your organisation. Strategic outsourcing of non-core processes can enhance overall efficiency of operations by enabling you to concentrate resources on your points of competitive strength.

For example, a tiny maker can ally with a specialist logistics firm instead of having a in-house distribution business, leveraging economies of scale and expertise they could not establish within.

Implementation Planning and Change Management

Even operational efficiency gains will be unsuccessful without effective implementation and change management. Here’s what to do to make your review result in actual improvements:

Strategic Outsourcing and Partnerships

Identify critical stakeholders impacted by suggested changes and involve them early on. Frame the business case for change in their priorities and concerns. Overcome resistance by explicitly communicating benefits and incorporating stakeholders in solution development.

Managing the Transition

Create a comprehensive transition plan that reduces disruption of current operations. Plan phased implementations, pilot implementations, or parallel operation of both new and old procedures during the transition phase. Ensure sufficient resources and support during the transition time.

Training and Skill Development

Evaluate training requirements for new technologies or processes and create training programmes that are thorough. Don’t forget that efficiency gains will need new working methods or skills. Give adequate time for individuals to master new styles.

Monitoring and Adjustment

Set precise measures to monitor the effects of changes made. Be ready to make some adjustments in accordance with actual performance. No implementation is totally as anticipated, and adaptability is key to success.

Continuous Improvement Framework

The most effective organisations treat operational efficiency as a continuous journey, not a discrete project. Having a continuous improvement framework ensures the maintenance and expansion of early gains in efficiency:

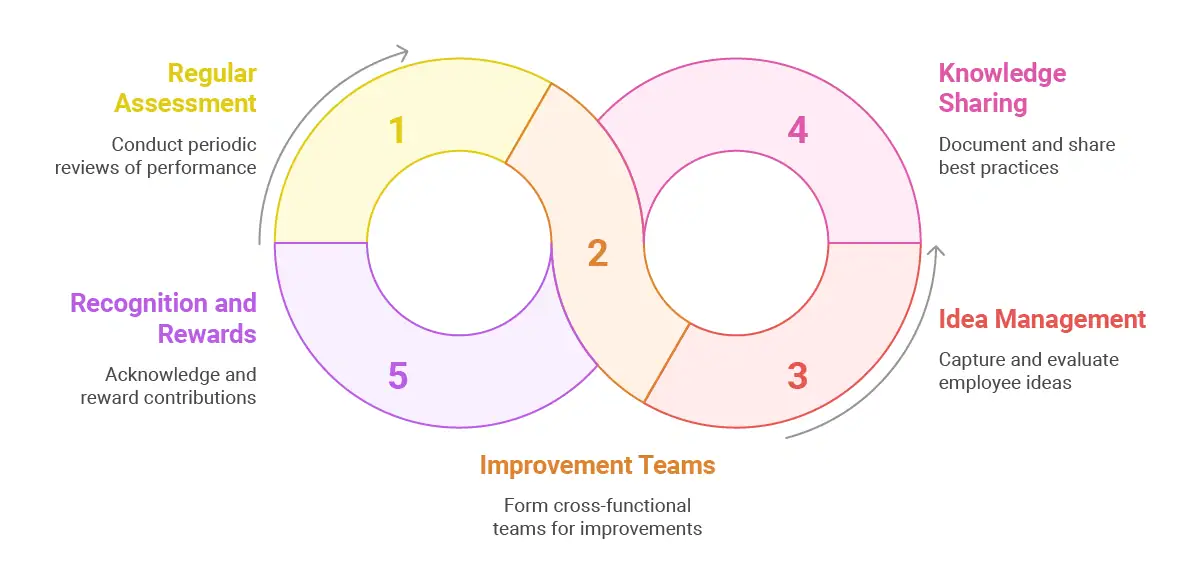

Regular Review Cycles

Plan recurring reviews of operations performance, perhaps quarterly for important metrics and yearly for more detailed examination.

Knowledge Sharing

Record lessons learned and best practices, transferring them throughout the organisation to avoid reinventing solutions.

Improvement Teams

Set up cross-functional teams tasked with finding and implementing areas of efficiency improvements.

Idea Management System

Develop formal means to capture, assess, and act on improvement ideas from employees at all levels.

Expected Outcomes and Benefits

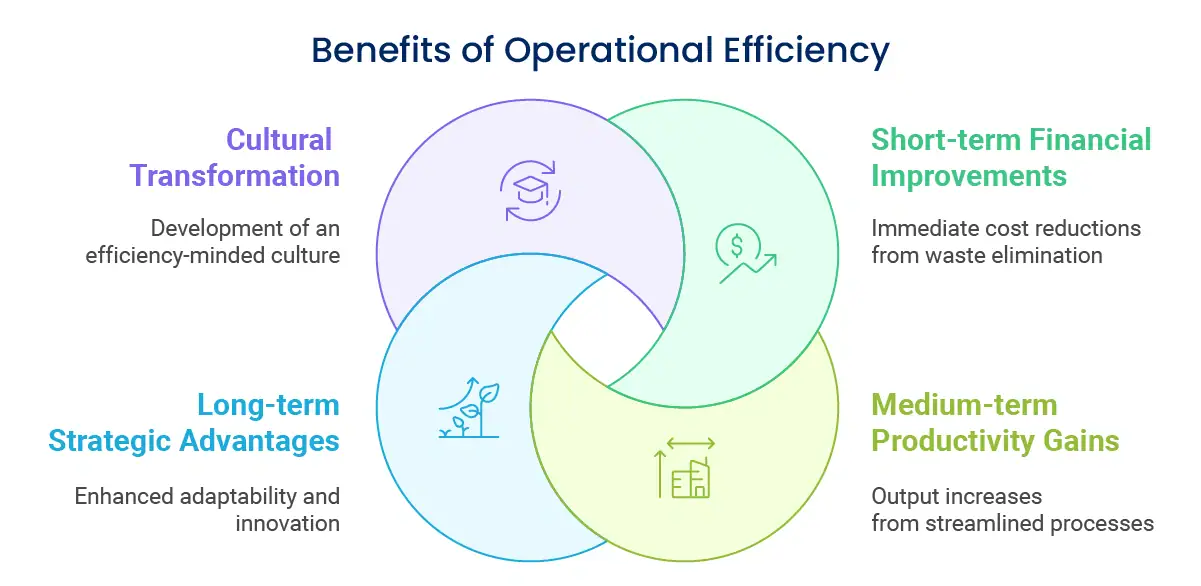

An effectively executed operational efficiency analysis will commonly provide several advantages:

Short-term Financial Gains

The majority of companies realize immediate savings from the removal of clear waste and inefficiencies.

Medium-term Productivity Benefits

With more efficient processes and improved tooling of resources, anticipate 10-25% increase in output using existing resources.

Long-term Strategic Benefits

Efficiently operating organisations can adapt more rapidly to changes in the market, grow more efficiently, and invest more in innovation because of reduced operating expenses.

Cultural Transformation

Most useful perhaps is creating an operational efficiency culture where everyone embraces constant improvement as a way of life.

Final Thoughts

Operational efficiency evaluation is not just about cost reduction—rather, it’s a strategic framework for maximising the value your company generates out of its deployed resources. By methodically reviewing your operations from perspectives of process flow, resource use, technology use, supply chain, and quality control, you are able to release tremendous performance, profitability, and customer satisfaction gains.

The best companies don’t treat operational efficiency as a one-off initiative but rather as an ongoing discipline that continuously evolves to suit changing conditions. Through regular assessment practices and a continuous improvement culture, you set your organisation up for success in competitive markets where the capacity to do more with less is the difference between leaders and laggards.

Need Help With Your Operational Efficiency?

At Brand Wisdom Solutions, we specialize in assisting firms in discovering and executing operational enhancements that yield quantifiable outcomes. Our experts blend analytical knowledge with real-world business acumen to develop solutions for efficiency that function in reality, not on paper. Investigate our business operations automation services to see how we can assist your company to operate at maximum efficiency.